The hardwood of different shapes is required for flooring work. It is difficult to make all kinds of cuts with a saw. It would be best if you had several types of saws, depending on the project. The flooring saw cutting shapes are ripped, crosscut, but they are less powerful. If you have a big project, please ignore this.

For that reason, many people use table saws, miter saws, and crosscut saws for hardwood flooring. These are portable, but you can use band saws in the industrial field. A band saw is very expensive, and it is possible to make all kinds of cuts.

Our best list includes table saws, miter saws, crosscut saws, and flooring saws that can help your hard woodworking.

Saw blades that are suitable for cutting hardwood flooring

The saw blades come in a variety of models. Each of the models differs slightly in its design, power, and vibrating patterns. Also, The same model’s hardwood blades have different vibration patterns, power, and sharpness. It depends on different companies manufacturing systems. The level of vibration also can vary by model. Each company has its type of saw blade, and they design and manufacture them differently. Hardwood Flooring Quality depends on the use of saw blades. There are many types of hardwood flooring blades

- Rip Blade

- Glue-line Rip Blade

- All-Purpose Steel Saw Blade

- Combination Blade

- Plywood Saw Blade

- Hi-ATB Blade

Rip Blade: With 20 to 30 teeth, you can cut hardwood with this rip blade. The standard rip blade has 24 flat-ground teeth.

Glue-line Rip Blade: This type of Blade has six more teeth than the standard rip blade. This Glue-line Blade with triple chip grind is very durable and will give you a smoother cut.

All-Purpose Steel Saw Blade: This type of Blade has 40 to 60 teeth and can be used for various tasks. You can do both crosscutting and ripping with this Blade, but you will not get the expected results.

Combination Blade: This Combination Blade has 80 to 100 teeth. You can cut precision miter cutting, laminates, and exotic hardwood. Also, this Blade works fast, so it is possible to cut any hard metals.

Plywood Saw Blade: This type of Blade has 100 teeth used in engineered flooring, moldings, and clean-cutting paneling.

High Alternate Top Bevel (Hi-ATB Blade): These blades are a modified version of the ATB blade through which ultra-smooth cut is available. Moreover, these blades have teeth in the range 34 to 98, and the teeth are curved 30 to 40 degrees with right and left angles.

4 Types of saw for hardwood flooring

1. SKIL 3601-02 FLOORING Saw Plus 36T Contractor Saw for flooring

The 3601-02 with 36T Contractor Blade is transportable. This Compact flooring saw is designed for cutting utility-grade materials up to 14 mm thick. You can use it to cut materials, including hardwood, timber, plywood, gypsum board, vinyl, and tiles.

Because of its lightweight design and compact size, the 3601 fits easily in your truck, motorcycle, or boat. You can take it anywhere, including up and downstairs, into tight spaces, or up onto a raised platform. But it’s not useful when working at heights and on jobs that require long periods of standing, chopping, sawing, and cutting.

The powerful 3601 has a 36″ top cutting depth. Moreover, it includes a handle that makes it easy to hold and maneuver for installation.

The 3601 allows you to combine the benefits of standard miter cuts, rip cuts, and crosscuts in one versatile tool. It can cut quickly from a full-size tabletop. Also, It gives you the power and control as a miter saw and crosscut saw.

The SKIL 3601 includes all the features and versatility, the same as a miter saw. In addition, the 3601 includes a free No-Fail Fitting Guide that covers the most common transitions, such as laying tile and laying wood in hardwood.

It’s easy to follow the simple one-button/one-light operation and makes it easy to see and understand how much lumber you’re cutting. If you need to create a beveled surface on your new trim, you can easily do that with this Saw.

Whether you’re a DIYer or a professional woodworker, the SKIL 3601 is an excellent choice to save time and money. It’s small enough to take with you for your home improvement projects. But it’s not powerful to do the work you require.

Pros

- Lightweight Design & portable

- vertical Workpiece clamp & dust port

- Can cut Cross, Miter & Rip Cuts

- Die-Cast Aluminum Miter and Rip Fence

Cons

- Low Quality

2. ROCKWELL RK3441K 4-1/2″ Compact Circular Saw

This RK3441K saw is very light and weighs just 5 Lbs. Also, it’s built quality well enough that easy to handle and runs very smoothly. The design doesn’t produce extra vibration or noise. A bigger light helps you see the work area. We liked the sturdy metal blade and self-sharpening head. The clamp is easy to use and applies precise cuts.

The RK3441K is a versatile saw that works well for multiple types of woodworking, including cutting two-by-fours, plywood, and MDF. At 4-1/2″ wide. Besides, it will easily cut two pieces of the same size. The mini power supply adds no bulk or weight and makes the saw easy to transport and set up.

This Rockwell circular uses a 5 amp motor that can rotate 3,500 RPM (revolutions per minute). This model includes a lockable storage bin with a shallow tray designed to hold small sheet goods and bulk items, so you can get your work done quickly.

The saw is set up with a steel bar stock that gives a strong sense of contact. The saw comes with a 90° surface blade for cutting thicker materials. You can rotate the clamp and handles up to 45° to cut on the front or back, plus it can flip over for sawing outside corners and thin scraps. A solid aluminum block protects the power supply when the saw is not in use.

It’s designing in such a way that protects the power switch from direct impact. It’s pretty quiet, even with cutting, though you will be able to hear the saw from some distance. As a premium, the saw comes with a dust port to keep dirt to a minimum.

The RK3441K is well-built, simple to use, and well-made compare with the price. It’s not a luxury model, but for those just starting and who don’t need anything fancy, the RK3441K provides an impressive first workbench for home workshops.

Pros

- lightweight and Compact design

- Saw Grip’s ensures balance and control.

- LED light provides clear visibility

Cons

- Can’t cut thicker wood

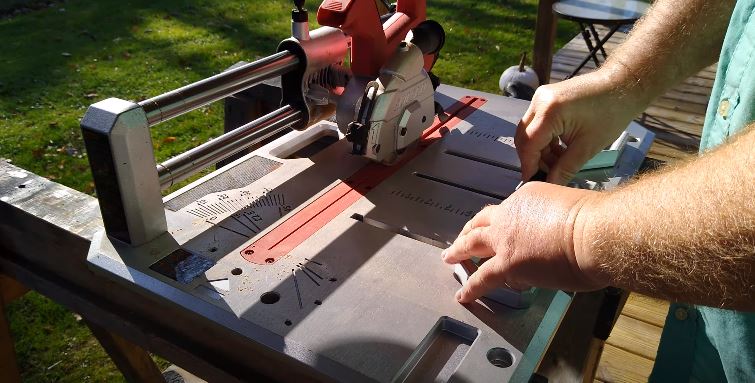

3. Rockwell BladeRunner X2 Portable Tabletop Saw for hardwood

Do you need to work in tight spaces and high humidity? If yes, then Rockwell Bladerunner X2 Tabletop Saw is the best choice. It is designed for cutting all kinds of wood and masonry material.

This model cuts various materials such as 2×4 boards, cinder blocks, hardwood, wooden uprights, plastic, metal, aluminum, etc.

For people who need a table saw in different home situations, it’s lightweight enough to carry. While the large space-saving dimensions can make this table saw best

With 300 RPM cutting speed, you can use a balanced carbide blade to give you a clean cut. But the steel blades are great for sharper cutting and thicker blades that can give you maximum cuts.

The table saw comes with a variable-speed motor, nice storage options, and various tabletop accessories. Also, the table saw comes with five different t-shank blades. It is an effective table saw that is perfect for hardwood. Simple design and portability attract lots of people. Besides, You need to be very careful when using this Saw because of the small handle. Also, it the sharp and could easily hurt your fingers.

Pros

- It’s super strong & portable

- High cutting speed

- Expensive but better than other table saw models

- Great deal for your hardwood flooring installation

Cons

- Not suitable for every hardwood floor installation

- Sometimes it jams

4. DEWALT DWS780 12-Inch Double Bevel Sliding Compound Miter Saw

DeWalt DWS780 12-Inch Double-Bevel Compound Miter Saw comes with a 15 amp motor that delivers 3800 RMP speed. It cut the hardwood through the saw as a piece of paper, especially when I use it for flooring wood.

It ensures no cutting stoppage at high speed and also ensures you have no power interruption. Also, there is a special blade sharpening system that assures your blade is always razor-sharp at all times.

It includes 14 positive stops technology. You can cut wide flat surfaces(such as floors and doors) without noise from the blade. The cut is also smooth, durable, and fast. It offers a variety of cutting capabilities for home-based or professional woodworking jobs.

However, this DEWALT double bevel 12-inch sliding compound miter saw is suitable for hardwood cutting and softer woods such as MDF. This Saw would be best for finishing other hardwoods like plywood, particleboard, etc. You can also use this Saw for fences, countertops, and doors. This Saw is so lightweight and portable.

The DWS780 allows crosscut and bevel cuts. Its cutting blade will ensure you cut the right angles and also make the best possible cuts. Also, the Saw comes with a carbide blade and one blade wrench. You can install the bar on the box unit. It makes it easy to transport and use. Moreover, the DEWALT DWS780 Miter Saw is also very versatile and convenient.

The Compound Miter Saw’s Hands-Free Control allows the user to adjust the blade to the optimal cutting angle quickly. The Saw also comes with a LED light and storage compartment that allows the user to clear cuts and safely transport the Miter Saw without risk of it falling out.

Moreover, the dust duct and miter lock technology is designed to cut the selected material to the desired dimensions in the direction of the blade’s movement.

Pros

- High cutting speed

- LED light indicator

- Cut thicker wood.

- powerful motor for heavy materials cut

- Great for hardwood flooring installation

Cons

- Too much weight

What to looks at before buying a saw for Hardwood Flooring

Power

There are different types of hardwood: Western red cedar, hickory, ash, black cherry, maple, oak, cypress, maple, pine, etc. The most commonly used hardwood is the hardwood of maple because of its anti-bacterial property.

You don’t know which wood to face when you work. So always take a powerful saw so that it applies to all types of woodcutting. It is always advisable to get a hardwood saw that can get the job done with just one hand and at the same time be good enough for professional working.

Adjustable speed

Speed control is essential in the case of electric saws for cutting hardwood materials. Most saws have two to three variable speeds. Try to take the ones that can be adjusted speed.

The handle

The best wood saws have a flexible handle that provides comfort and ease to the user. Therefore, you will not suffer from back pain during the whole working process.

Universal clamp

You will notice two types of clamps in the market. Some companies use T-shank saw blades, and some use U-shank saw blades clamp. Select the one that has both clamps.

Wattage

The Wattage parameter is important for each electrical device. The higher the watt, the higher the efficiency of the motor and the better the results. But more watt electrical equipment wastes more electricity. So select Wattage Requirements as per your requirement.

Keyless blade replacement & Blade bore.

There is no need to consider when buying a blade bore diameter saw, but based on the work, you must choose one that suits your job.

The advantage of the keyless blade replacement feature is quick blade replacement. This function will be very effective if you have work pressure.

Dust extraction & Shoe plate

These two things are very important for Hardwood Flooring. The main function of shoe plates is to cut wood at an angle. Angle cutting is very important for flooring, so choose a saw with the Shoe Plate feature.

A lot of dust is produced while working with a saw. All the dust collection is done by the dust collector function and brings clean fillings to work.

Additional cut

In the case of flooring, the work doesn’t complete by cutting and installing the hardwoods. At the end of the work, it is necessary to polish the hardwood’s symmetrical surface and finish.

The chopping cut is usually the shortest one, and you can use it to get a part of the Goodwood’s surface for polishing, finishing, and whatever purpose. It is also known as cleaver cut.

You can use the planning cut to get a smooth and straight surface. As it is usually used to prepare the base for the sanding operations and make the surface at an angle for sanding. Lastly, the running cut is used to get a symmetrical surface and one final planing layer. Special saws to which polishing and sanding discs can be attached separately.

The price

When choosing the best wood saw for hardwood flooring, consider its capacity and the amount of weight and cost for the same. It is important to get a saw at a reasonable price and handle the weight of the wood.

How to Use A Saw For Hardwood Flooring

The chances are good that you will use a table saw or other power saw for wood flooring. It is an important task to finish the hardwood floor before the flooring is installed. It’s also a big job, and the right tools are needed to accomplish it. Follow the directions here carefully, and you will be ready to finish your floor.

Hardwood Flooring cutting & Safety instructions (Table saw)

Here are a few things you can do to ensure that you are ready for your wood flooring operation.

- Be sure that the saw blade is level. Make sure that the saw blade is working. You should feel a small vibration. The Blade is cutting to shape.

- Step down the Blade before you begin cutting. Do not lower the Blade down very far, or the wood will be too long for the saw.

- The Blade must be working smoothly. Remember that the Blade is very sharp, so Anything that you have laying on the wood can get ripped off.

- Cleaning the saw is another important step. To clean the saw, you will need a shop-vac or a pressure washer.

- Keep your hands away from the cutting edge. You don’t want to cut your fingers.

- Now you will begin cutting the board to size. In most cases, a saw blade cut about 20 to 25 percent of the board’s width. You will be careful about it. Please ensure that you will not cut through the base. It’sIt’s a good idea to cut a sample board of the same thickness, so you can get an idea of how it will look.

- The hardwood may break if it has any error. When cutting the wood, you want to be sure to put a piece of wood in between the board and the Blade so it does not become stuck. You can use a fence or something similar.

- When cutting, you want to make sure that the board does not move or flex, which can cause a crack in the wood. If it is necessary to sand or finish the area, you will be concerned with the condition of the boards.

- If it is not possible to sand and finish the wood, you can add a protective covering. It may not work in all cases.

- When cutting, it is also important to consider that you can’t cut through the wood wall. You will be cutting into the subfloor and the underlying joist. It will need to be maintained. When cutting into the subfloor, be sure to use low-impact cuts that will not damage the subfloor.

FAQ

What kind of saw to use for hardwood flooring?

Meter saws work well for hardwood flooring. But the miter saw is much better for crosscut but can do a rip cut. Many people prefer to use a table saw for rip cutting. You can cut tiles and wood with a flooring saw. But in the case of flooring, it may be necessary to cut wood in almost different shapes. That’s why miter saws, floor saws, and table saws are all needed. You will get all these benefits in band saw. But band saws are not portable. Those that are portable are more expensive.

Can you use a laser blade saw for hardwood flooring?

Laser Blade Saw is good for Hardwood Flooring and can be used to get the perfect cut. The Laser Blade Saw Blades are highly powerful. They also can cut hardwood in a wide range of thicknesses. The saw blade vibrates in the laser to cut the wood. It is a major difference between the Micromatic blade saws and the laser blade saws. Micromatic blades do not vibrate so much because the vibrating surface on the Blade is much larger than the Blade itself.

The laser blade saws are also excellent for outdoor cutting. The laser blade saws can last for several years for a job where you cut wood and put it in a trailer to transport them. On the other hand, the blade saws will wear out much more quickly.

These are only used in industrial cases and large projects. If you have a big industry, then you can try. Laser lights are placed in front of many saws, through which you will get the cutting direction. But in the industrial field, these saws work in an automated way.

Hi their! I am working with daily instruments since 2018. I complete my M.SC in Mechanical Engineering. I accomplished with commencement in 2009 from the College of Colorado Denver. Now I am working for a widely known tools firm. Sometimes i write informative article on my blog weeklytools.com & dailytools.com